Dynamic make POT-PTFE Bearings represent the next generation of bridge bearing technology, specifically engineered to address the complexities of contemporary bridge structures. With the rise of longer-span and continuous bridges, coupled with compound curves and heavier truckloads, modern highway engineering demands bearings that can endure larger loads and movements concentrated on fewer piers.

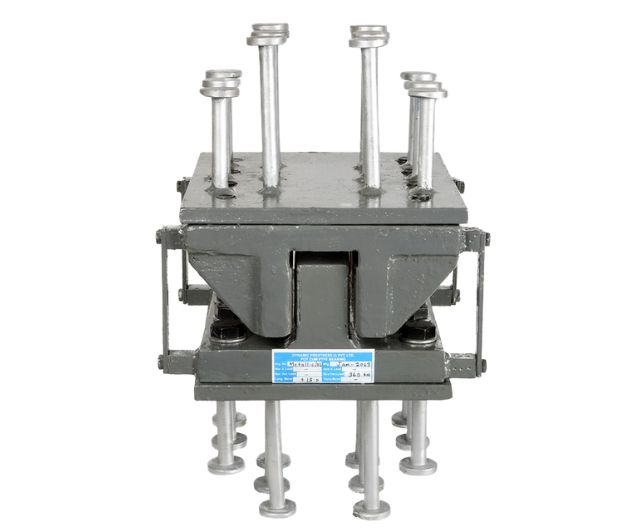

These Bearings are consisting of metal piston supported by a disc of unreinforced elastomer that is confined within the metal pot. This bearing may be provided with sliding assembly comprising of Stainless-steel plate welded to the Top plate sliding in horizontal plane over PTFE. These Bearings are provided with Anchoring arrangement connecting with Bottom & Top Structures. Depending on the desired functioning. Pot bearings may be three types. Fixed Pot Bearing Guided Sliding POT cum PTFE Bearing Free Sliding POT cum PTFE Bearing.

Dynamic Pot Bearings are available in Four types to suit specific design and functionality needs:

Our in-house manufacturing and testing facility holds approvals from various NHAI Projects, RDSO (Research Design & Standards Organization), State PWD’s and various State Road Development Corporations. Over the years, numerous clients and consultants have visited our factory, endorsing our manufacturing processes and bridge bearings after observing rigorous testing.

Dynamic leverages cutting-edge machinery to ensure precision and efficiency in the production of high-capacity pot bearings. Our commitment to quality and innovation, solidifies our position as a trusted partner in infrastructure industry. With a capacity of up to 2,000 tons, these bearings have been integral to numerous high-profile bridge projects.

Recent accomplishments include following few projects:

Dynamic bearings ensures top-notch quality by adhering to rigorous quality control protocols. Each pot bearing undergoes meticulous checks at every stage of manufacturing, with comprehensive documentation maintained for every unit. The final products are tested in strict compliance with code specifications, ensuring reliability and durability.

A key element of the pot bearing is the elastomeric disc or pad which acts like a fluid under pressure, permitting the rotation. So sealing is very important part between pot & piston to ensure the correct functioning of this pressure pad. We are providing POM (Poly Oxy Methylene) sealing chain which consist of individual interlocking elements made of moulded polyoxymethylene having properties & size.

The fixed pot bearings are engineered for reliability and performance, comprising a pot,elastomeric pad, and top plate.

These bearings are designed to:

Bear and transmit vertical loads efficiently.

Handle horizontal forces in any direction.

Allow rotation about any axis in the horizontal plane while restricting movement in the horizontal plane.

This precise combination ensures stability and adaptability in demanding construction applications.

Engineered to bear and transmit both vertical loads and horizontal forces.

Enables movement in all directions, ensuring flexibility.

Facilitates rotation around any axis within the horizontal plane.

Effectively counters uplift forces, even under minimal vertical load conditions.

Features a specially designed “Anti uplift arrangements” to restrict upward movement.

Guided Sliding Pot cum PTFE Bearings are engineered with a combination of high-quality components, including a POT, Elastomeric pad, Piston, Sliding Material (PTFE sheet / DynaSlide), stainless steel plate, and top plate. These bearings are designed to efficiently bear vertical loads while transmitting horizontal forces in one direction. They also allow movement perpendicular to the applied force and provide rotation around any axis in the horizontal plane.

Based on their movement capabilities, these bearings are categorized into two types: Longitudinal Guided POT/PTFE Bearings, which allow movement in the longitudinal direction, and Transverse Guided POT/PTFE Bearings, designed for movement in the transverse direction.

The stainless steel plate is mirror polished ensuring smooth movement of the top plate while reducing friction for optimal performance.

Free Sliding POT cum PTFE Bearings are crafted with high-quality components, including a POT, Elastomeric pad, Piston, Sliding Material (PTFE sheet / DynaSlide), stainless steel plate, and top plate. These bearings are designed to support vertical loads while enabling movement in both directions. They also allow rotation around any axis in the horizontal plane.

The stainless-steel plate is mirror-polished, ensuring smooth movement of the top plate and minimizing friction for enhanced performance.

Pin bearings features a metal pin housed within a metal cylinder, designed to bear and transmit horizontal forces in any direction along the horizontal plane. They also accommodate rotational movement about any axis.

Note: Pin bearings do not support or transmit vertical loads.

The anchoring system includes backing plates and studs to securely fix the bearing to the structure.

Metallic Guided Bearings are designed to transmit horizontal forces while allowing movement in a perpendicular direction. The sliding assembly provides precise restraint along the desired path, with rotation limited to an axis perpendicular to the sliding plane.

These bearings do not support or transmit vertical loads.

The anchoring system includes sturdy backing plates and studs, ensuring secure attachment to the structure for optimal performance.

Bearings are the vital part of any bridge super structure. The primary function of Bridge Bearings is to accommodate expansion and contraction due to changes in temperature and humidity and to reduce friction caused by the traffic loads on substructure of the bridge.

Elastromeric (Neoprene) Bearing

Sliding Elastromeric Bearing (with PTFE Sheet over)

Stopper Elastromeric Bearing

Fixed Elastromeric Bearing

Strong

Hard still flexible

Weatherproof

Economical

Durable

Maintenance Free