Dynamic sheathing ducts, made from steel or plastic, are embedded in concrete structures to create the necessary voids for the accurate placement and alignment of post-tensioning strand tendons. For internal tendons, corrugated round plastic ducts (HDPE) complying with FIB Bulletin 7 & 75 standards are used.

The sheathing is corrugated and manufactured from CRCA strips in various diameters, ranging from 39 mm to 200 mm. Available in both bright metal and galvanized finishes, the sheathing meets the specifications outlined in IRC 18-2000 and IRC 112-2011.

Friction Loss Values:

Single-Walled Corrugated (SWC) Sheathing Ducts are essential for insulating prestressing strands and cables in the construction of critical infrastructure, including highways, railway bridges, flyovers, offshore platforms, viaducts, buildings, nuclear containment structures, and underpasses. Available in wall thicknesses of 2.3mm/ 3mm/3.5mm/ ± 0.3mm. These ducts can be customized in a range of colours to meet specific project requirements.

Produced using advanced European machineries having microprocessor-controlled systems, our HDPE pipes ensure superior quality and consistent wall thickness, meeting the highest industry standards.

Advantages of SWC Prestressing Technology

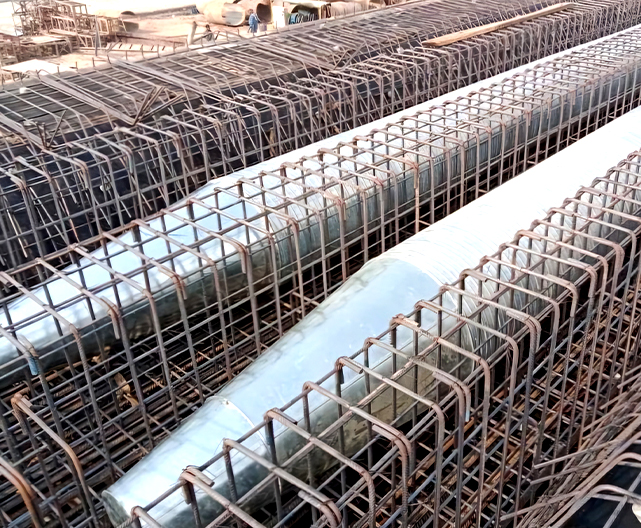

Dynamic void formers play a crucial role in prestressed and RCC concrete voided slab bridges, both in India and internationally. These void forming tubes are designed to meet the demands of concrete structures, offering a highly rigid yet lightweight solution that withstands the forces during pouring. To ensure optimal performance, it’s essential that the void formers are embedded in concrete without deformation, with proper support arrangements being just as critical as the quality of the void former itself.

Manufactured from C.R.C.A. steel strips, the void formers is supplied in diameters ranging from 300 mm to 1500 mm. The spirally locked and corrugated tubes feature 6-8mm corrugations with seams spaced no more than 120mm apart. The continuous corrugations allow individual lengths to be coupled using a 200mm standard coupler. The ends of the tubes are sealed with an end coupler or end lid for added durability.

Dynamic Group, a leader in prestressing technology, specializes in the design and manufacturing of high-quality void former tubes for the construction industry. These tubes are embedded into concrete structures to reduce cross-sectional area, resulting in significant concrete volume savings. The reduction in dead weight enhances the economy of substructure design. Featuring special corrugations for superior radial rigidity, Dynamic void formers are designed for easy installation on-site, minimizing transportation costs and saving valuable time.

Our void forming machines cater to a wide range of diameters, from 250mm to 1500mm, offering versatility for various project needs. Dynamic void formers have been successfully installed in numerous prestigious National Highway Projects like Galaxy Flyover (2000m), Yamuna Bridge (1000 m), and Delhi Flyover (1200m), among others.

Engineered to withstand concrete pressure without deformation, our void formers meet stringent requirements for concrete structures. Their seamless construction prevents water infiltration, while their lightweight design ensures easy handling. Internal seams and corrugations prevent tubes from catching on each other, simplifying the mounting of female end cones or caps.

The End Cone Lid or End lid is crafted from high-quality C.R.C.A. strip, precisely manufactured to the required dimensions, ensuring a secure cover for both ends of the void former pipe.