Dynamic offers multi-pull jacks/pumps for entire tendon stressing having capacities ranging from 100T to 1200T with stroke length of 200mm compatible with 12.9mm, 15.2mm, and 15.7mm strand systems. Built for efficiency and durability, they are ideal for diverse construction needs.

Tailor made jacks like smaller stroke length, front gripping, rear gripping jacks, compact diameter jacks etc. are also provided on request.

Dynamic offers a comprehensive range of Pre-tensioning Mono jacks and power packs, engineered for H.T. strands in diameters of 12.9 mm, 15.2 mm, and 15.7 mm, with strokes ranging from 30 mm to 1500 mm. For pre-tensioning work, we provide mono jacks and pumps with 10-ton to 30-ton capacities, featuring varied stroke lengths and optimized for use with wedges and barrels.

The Bulbing Jack is a specialized tool designed for creating bulbs on individual strands. This process is essential in scenarios where dead-end anchorages are required. These anchorages are used when one end of the tendon is embedded within the concrete, making it inaccessible for stressing due to space constraints.

For such applications, the other end utilizes a normal anchorage type, ensuring secure and efficient tensioning. In situations where jack placement is not feasible, a dead-end anchorage plate is employed to complete the process seamlessly.

(JACK DOWN EQUIPMENTS & ACCESSORIES)

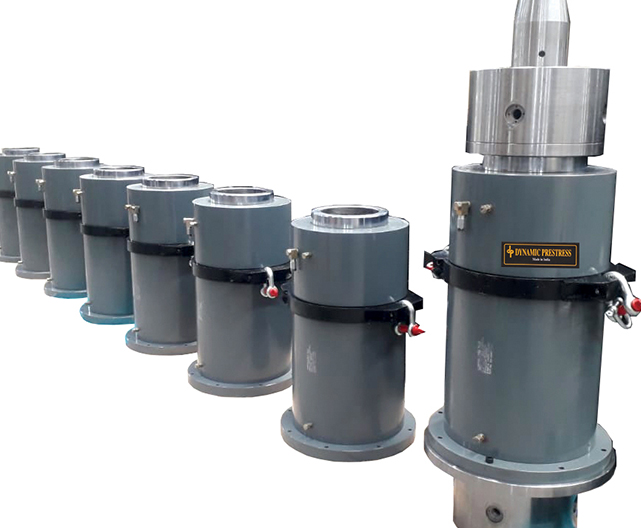

The Jack down method for well sinking is a precise and controlled method of sinking wells within the allowable limits of tilt, shift, and rotation at every stage. The basic principle of this method is to apply pressure over the staining wall using hydraulic jacks, which are connected to supports outside the well.

Prestress anchors are provided as a reaction to push the well downwards. This method has been successfully used in projects like the Narmada Bridge in Gujarat, Second Nizamuddin Bridge in Delhi, Yamuna Bridge in Delhi, and for intake well sinking at the Simhadri Thermal Power Project in Vizag, MASHR C-4 , C-6 for high speed rail project The Jackdown method has proven to achieve controlled sinking with minimal tilt and shift, resulting in significant savings in time and cost.

Controlled Sinking

Significant Time and Cost Savings

Speedy Operation

The Jackdown method utilizes specially designed jacks, along with essential accessories like gripper rod assemblies and reaction beams, to drive the well to the required depth. The capacity and number of equipment are carefully determined based on factors such as driving force, the number of feasible anchors, and the specific conditions of the surrounding strata. The force applied to the well is calculated considering elements like cutting shoe resistance, float, and negative skin friction.

This proven and efficient method is trusted by construction companies worldwide for its reliability and effectiveness in well sinking projects.

Our dynamic pushing jacks, with capacities ranging from 100 tons to 800 tons or more, are engineered for simplicity and ease of operation. These robust systems are designed to facilitate the precise movement of concrete structures and elements, particularly in group pre-tensioning applications. Available with customizable stroke lengths, our pushing jacks are built to meet the specific needs of your project.

We maintain rigorous quality control standards, ensuring the highest levels of reliability and performance, from the careful selection of raw materials to the final commissioning of the equipment.

For lifting heavy loads, we utilize specially designed lifting jacks and tackles, incorporating the proven strand lift system. Widely recognized for its success in India and across international markets, this technique is ideal for lifting multi-flue cans, steel, and concrete girders, delivering exceptional results in even the most demanding environments.

Our strand lift jacks are engineered to lift heavy machinery, pre-cast girders, flue cans, and more. These jacks are compatible with various sizes of high-tensile strands, making them versatile for a range of lifting applications.

In our Strand Lifting System, jacks and accessories, along with the reaction beam, are mounted atop the structure. High-tensile strands of the required capacity are connected to the lifting element using the appropriate brackets. The element is then lifted step by step, factoring in both the jack's stroke height and the height of the element, ensuring precise and controlled lifting operations.

Dynamic's innovative re-stressable anchorages are designed for specialized projects, enabling the recovery of prestress losses over time. These anchorages feature a uniquely threaded bearing plate on the perimeter, facilitating effortless re-stressing operations. A custom-engineered jack complements the system, ensuring precise and efficient tendon re-stressing whenever needed. This advanced solution empowers infrastructure durability and long-term structural performance, setting a new benchmark in prestressing technology.

The Dynamic Mechanical Bar System is designed for compatibility with Macalloy bars, offering efficient solutions for high-strength applications. Hydraulic bar jacks are available for Macalloy bars up to 75mm in diameter, with flexible sizing options to meet specific project needs.

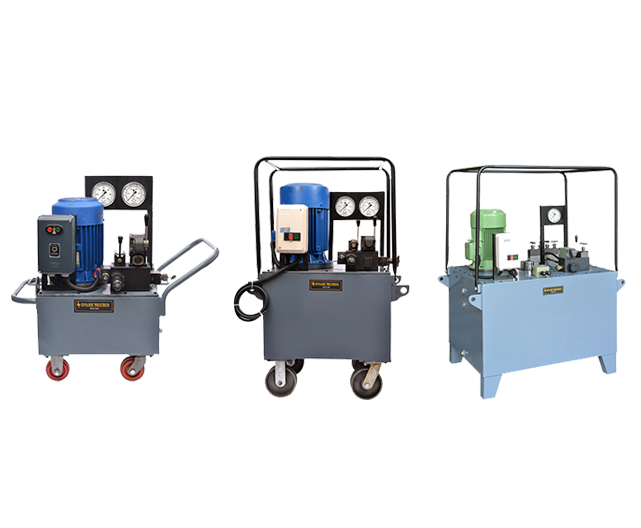

Dynamic's hydraulic power packs are self-contained units comprising of motor, reservoir and hydraulic pump designed for efficiency and reliability.

Applications:

Dynamic’s power packs are engineered to operate a wide range of hydraulic jacks, including:

Multiple Hollow Jacks

Multiple Flat Jacks

Pushing Jacks

Lifting Jacks

Pile Load Test Jacks

Well Sinking Jacks

These robust power pack system deliver precise power for demanding tasks across construction, infrastructure and engineering projects ensuring superior performance and durability.

Dynamic offers single and double-drum electrically operated grout agitators tailored for precise grout mixing needs.

Key Features:

Enhanced Efficiency Uniform Mixing: Equipped with a vertical shaft, specially designed blades, and baffles, these agitators ensure homogeneity by preventing material separation.

Adjustable Speed: Paddle rotation speeds are adjustable up to the specified RPM for optimal mixing.

Easy Cleaning: The design of tank ensures proper cleaning of grout

Dynamic's grout agitators deliver reliable performance, meeting the rigorous demands of prestressing and grouting applications.

Dynamic's high-performance grout pump is engineered to pump cement grout under controlled pressure, making it ideal for grouting prestressed tendons. Its versatility extends to consolidation grouting in dam construction, ensuring water tightness by sealing holes effectively.

Importance of grouting in PT works

Grouting is critical in post-tensioning works, serving to:

Prevent Corrosion: The grout creates an alkaline environment that safeguards tendons.

Enhance Bond Strength: It forms a robust connection between prestressed steel and concrete.

Improve Structural Integrity: Properly mixed grout offers homogeneity, fluidity, and high compressive strength.

This HDPE & PP coupler ensures leak tightness of the ducts at segment joints. The leak proof coupler maintains the integrity of the tendons across the match cast joints while allowing easy installation and construction tolerance. A precast concrete segment is cast against the preceding segment producing a matching interface which permits the re-establishment of cast geometry at erection time. Match casting is achieved by either short line or long line casting method.

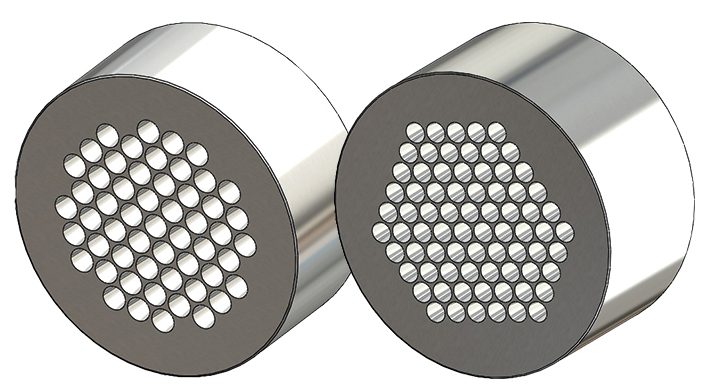

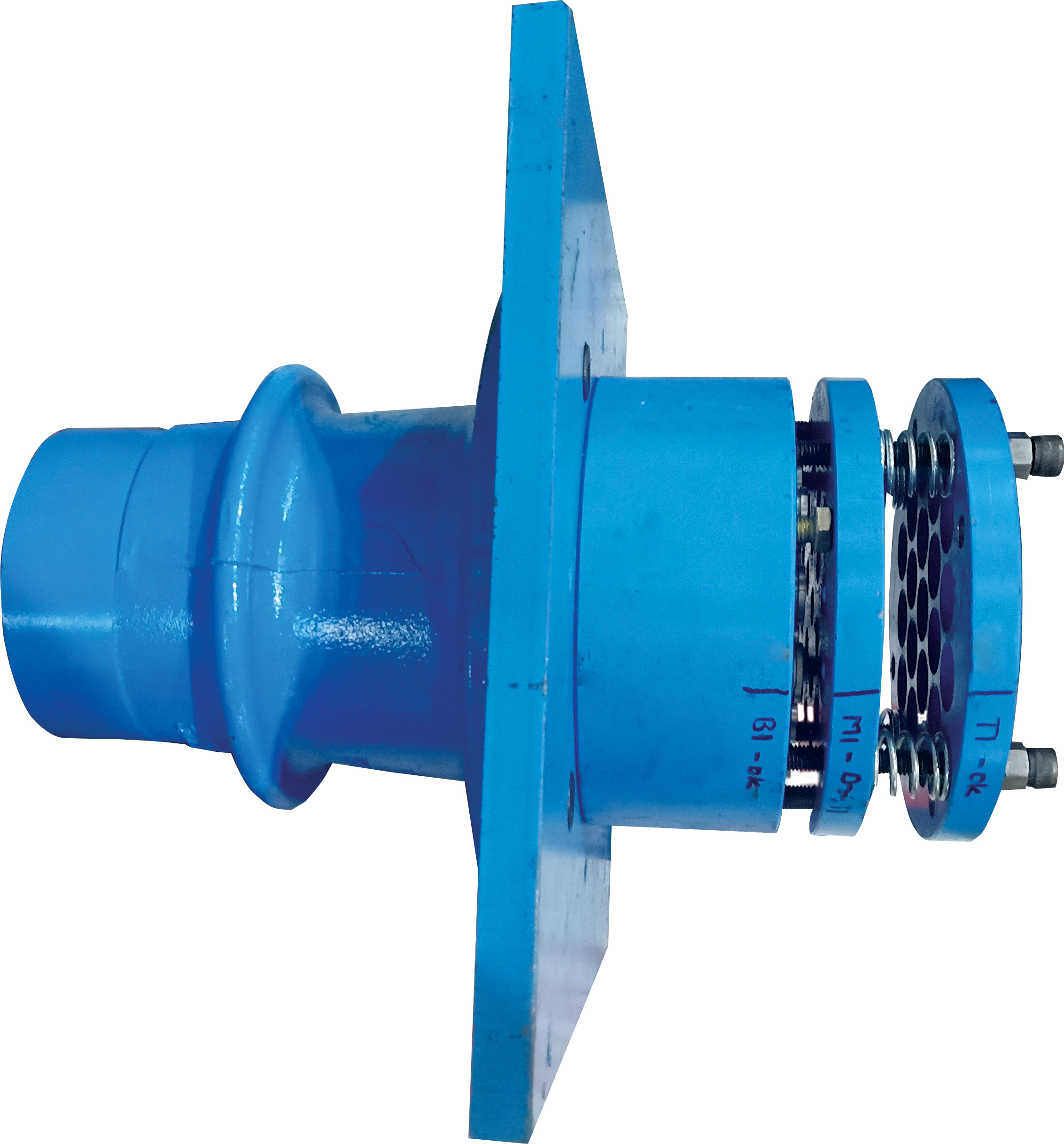

Embedded Dead end anchorages are used at non stressing end of a tendon. They are used where the end of a prestressing cable is buried in concrete or is inaccessible during the stressing operation of the tendon. The wedges are locked in place by the spring-loaded mechanism.

Dynamic Prestress has state of art CNC & VMC machines which can precisely produce very high capacity anchor block for 55 strands, 75 strands and above, which are extensively used for stay cable bridges & extra dosed bridges.